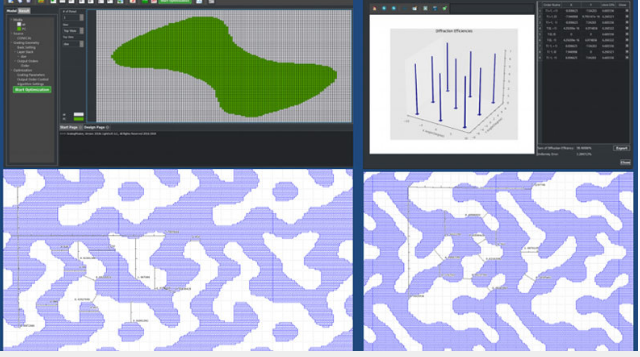

|  Customized DOE design software Customized DOE design software

Our team have deep understanding in DOE design theory and rich experience in DOE design. We have the ability to customize commercial DOE design software, and are developing in-house DOE design software. We also developed direct data exchange interfaces for self-developed spiral laser direct-write devices.

|

Patented spiral laser data encoding Technology Patented spiral laser data encoding Technology

Our team has complete and strong customization experience and capability in restructuring the existing spiral laser direct writing equipment. We already have a special redesigned DOE spiral laser direct writing (LBR) system and a spiral laser data coding patent and independent, unique data file format. The exposure speed of the system is 10-25 times faster than that of traditional laser direct writing. Our technology enables any shape of micro and nano devices to be processed, with a minimum feature size of 300 nanometers. It can be further shrunk to 200 nanometers in the future. |

|

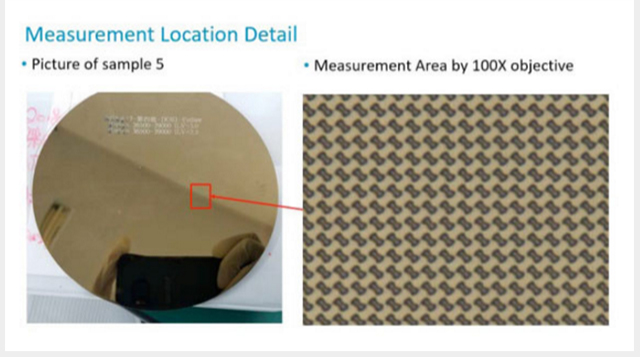

|  Complete DOE production process and technology Complete DOE production process and technology

Our team owns complete DOE manufacturing process and technology, including DOE design, master preparation, batch injection molding replication, DOE quality testing, etc.

|

Huge capacity advantage of plastic injection molding process Huge capacity advantage of plastic injection molding process

Compared with traditional photolithographic process, our unique process enjoys low material cost and process cost advantages. The company is operating 22 injection molding machines for mass production. We have solved the issue of high temperature resistance of plastics with automatic testing equipment.

|

|